charpy v-notch impact test 涓枃|charpy v notch testing standard : trading In 1896, S. B. Russell introduced the idea of residual fracture energy and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont . See more WEBDownload scientific diagram | ZZZZWWWWW Guascas, Nariño. from publication: El Colapso de la Hipótesis de Estacionariedad por Cambio y Variabilidad Climática: .

{plog:ftitle_list}

A programação do Canal Eleven Sports 3 para este dia não está disponível de momento. Guia TV Canais Relacionados. Eleven Sports 3; Canais Populares; Todos os canais; No ar agora; Futebol na TV; Filmes no Cinema em Cartaz. Filmes em exibição Filmes em Estreia

charpy v notch toughness

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it . See moreIn 1896, S. B. Russell introduced the idea of residual fracture energy and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont . See moreThe quantitative result of the impact tests the energy needed to fracture a material and can be used to measure the toughness of the material. There is a connection to the yield strength but it cannot be expressed by a standard formula. Also, the . See more

According to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: . See more

charpy v notch testing standard

charpy v notch testing requirements

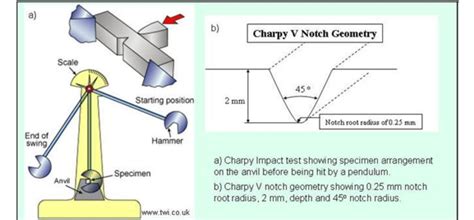

• Izod impact strength test• Brittle• Impact force See moreThe apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the . See moreThe qualitative results of the impact test can be used to determine the ductility of a material. If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with . See more

The impact energy of low-strength metals that do not show a change of fracture mode with temperature, is usually high and insensitive to temperature. For these reasons, impact tests . See more

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

sampling techniques in quantitative research

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture.

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact test, also referred to as Charpy v-notch test, is a materials testing method used to determine the impact strength of materials using a pendulum impact tester. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .

Charpy V-notch (CVN) impact-test results are used widely in various toughness specifications even though the energy absorption values cannot be related directly to structural design. Conversely, K Ic , the plane-strain stress-intensity factor at onset of unstable crack growth, can be related to structural design, but K Ic test results usually .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample.

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. A modification in the existing empirical relation correlating the Charpy V-notch impact testing results with plane strain fracture toughness is suggested. The estimates of fracture toughness from the present modified emperical correlation are found to be in good agreement with the valid fracture toughness test values obtained from compact . The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for comparing the toughness of different metals but is more suited to providing information on the behavior of a single material at .

As was written, toughness can be measured by the Charpy test or the Izod test.These two standardized impact tests, the Charpy and the Izod are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used.

The Charpy Impact Test, also known as the Charpy V-notch test, is a crucial method in the field of materials testing. This test helps determine a material’s ability to absorb energy and resist breakage under high-velocity impacts. Utilised widely in industries such as construction, automotive, and aerospace, the Charpy Impact Test provides .

impact testing. This Standard is Method 2 of a series of Standards on the methods for impact testing of metals. The series comprises the following methods: AS 1544 Method for impact tests on metals 1544.1 Part 1: Izod 1544.2 Part 2: Charpy V-notch 1544.3 Part 3: Charpy U-notch and keyhole notch 1544.4 Part 4: Calibration of the test machine The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures. Learn more about the .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base. U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch.ESIS TC5, “Proposed Standard Method for Instrumented Impact Testing of Sub-Size Charpy V-Notch Specimens of Steels” (Annex C), Draft 10a, 23/5/02 [10] Lucon E., Round-Robin On Instrumented Impact Testing Of Sub Size Charpy-V Specimens: Results Of Phase 1”, ESIS TC5 Instrumented Impact Testing, Final Report, 2 April 1998 [11]

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation . Charpy V-Notch: 55 mm length, 10 mm width, 10 mm thickness, with a 2 mm deep notch and a 45° angle. . The Class D – Charpy Impact Tester is a dual-column system specifically designed for Charpy Impact .

Charpy V-notch testing of linepipe steels is carried out according to ASTM E23 (American Society for Testing of Material) [6]. The standard full-size specimen (10 mm × 10 mm × 55 mm, a 45° V . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve?

Drop-Weight and Charpy V-Notch Tests. Examining the Charpy Effect Metals’ impact resistance or toughness can be measured by subjecting them to impact testing, which involves measuring the amount of energy absorbed by the material before it breaks. To determine if the impact energy is affected by temperature, the test is carried out at a range of temperatures.Plastic V notch impact sample 80*10*4mm Organic glass V notch impact sample 80*10*4mm . By testing plastics with the Charpy test method the impact resistance of the plastic can be determined. Charpy impact testing can also be used to determine the sensitivity of notched plastics specimens. Impact resistance of plastic notched specimens measures . he Charpy V – Notch Test is a popular choice for dynamic impact testing of metals. The standard test features a fixed mass The standard test features a fixed mass pendulum with an attached impactor.The Charpy V notch test, or Charpy impact test, measures the energy absorbed by a material during fracture. The destructive test method consists of a pendulum, hammer, and a beam of metal placed between two anvils. The energy required to fracture the material provides insight into the material’s notch toughness at various temperatures.

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

The Charpy V-notch impact test is performed by machining ‘V’ notch in the centre of the standard test specimen and the test specimen is fractured at a test temperature by a swinging pendulum of a known potential energy. The test specimen absorbs portion of the energy to fracture and this absorbed energy is indicated by the machine. Rupture strain, yield, and ultimate tensile strengths of the alloys were determined by tensile testing. Charpy V-notch test results revealed that the energy absorption ability of the 6061-T6 Al .

charpy v notch test procedure

a strong negative influence on the impact energy measured through Charpy V-Notch testing. It was not possible to model more complicated steel alloys. This was due to the different precipitation processes being utilized for other grades. A514 uses Nb, V and/or Ti to form carbides and fine grain sizes. Without bringing in the processing .

The Charpy specimen may be used with one of three different types of notch, a 'keyhole', a 'U' and a 'V'. The keyhole and U-notch are used for the testing of brittle materials such as cast iron and for the testing of plastics. The V-notch specimen is the specimen of choice for weld testing and is the one discussed here.

Nacional Inn São José dos Campos 4*. Localizado muito perto de shopping e supermercado a 13 minutos de carro da Catedral de São Dimas, Nacional Inn São José dos Campos Sao Jose dos Campos charmoso oferece 36 quartos a cerca de 3.2 km do Museu Municipal de São José dos Campos. Todos os hóspedes podem desfrutar de Wi .

charpy v-notch impact test 涓枃|charpy v notch testing standard